R&D

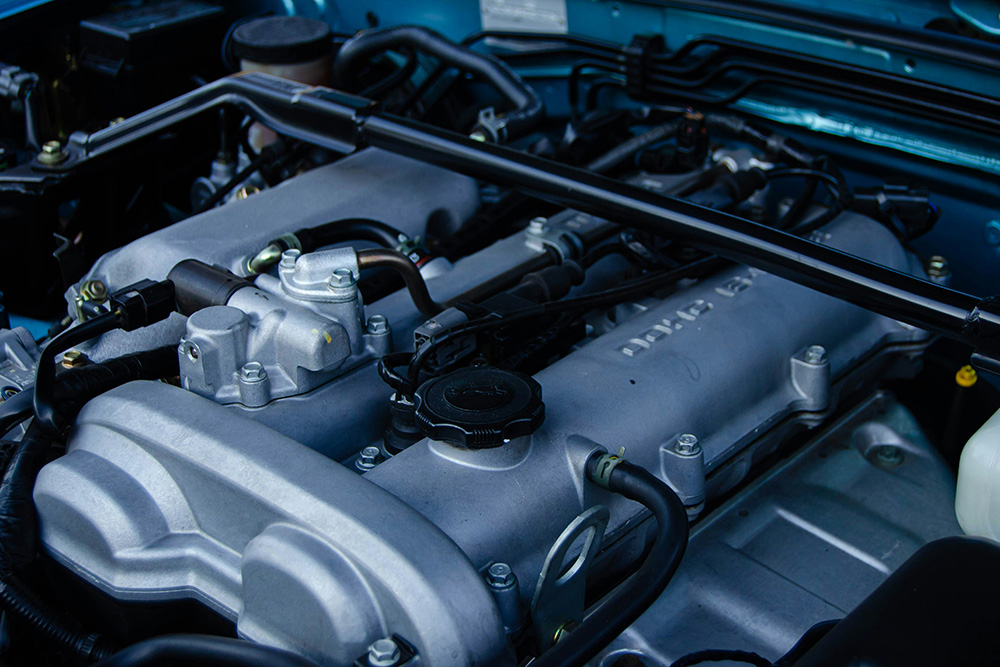

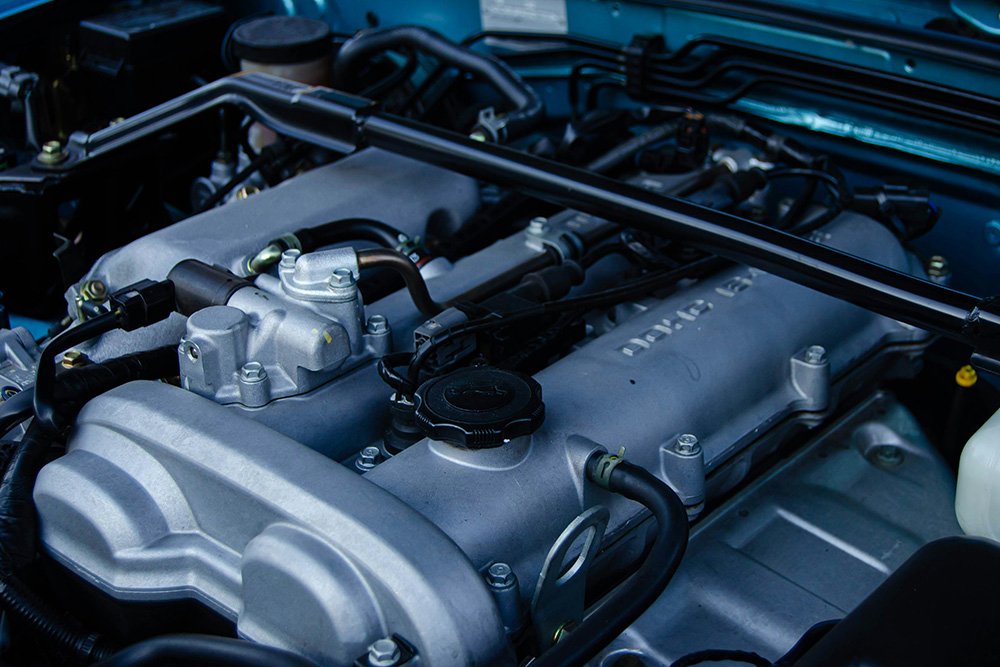

Reliable OEM supplierspecialising in high-precision automotive engine parts

Wellgine is a trusted OEM manufacturer of precision automotive engine parts, including oil pumps, camshafts, vacuum pumps, and electric water pumps. We focus on quality, reliability, and performance in every stage of production.

Technical Team

Experienced Engineers in Auto Parts Development

Our engineering team consists of experienced professionals dedicated to the development of precision automotive parts, including camshafts, oil pumps, VVT units, and vacuum pumps. With strong knowledge of OEM standards, materials, and engine systems, they combine advanced design with hands-on manufacturing expertise.

Working closely with R&D, quality, and production teams, our engineers ensure each product is technically accurate, thoroughly tested, and built for long-term reliability. From 3D modelling to prototyping and mass production, we deliver practical, high-performance solutions for both the aftermarket and OEM-equivalent markets.

R&D Process with Quality at Its Core

Our R&D process is meticulously designed to embed quality at every stage, from initial concept to final product validation. Starting with thorough market research and feasibility studies, our engineers develop precise designs which undergo multiple rounds of review and testing. Prototypes are rigorously evaluated under simulated real-world conditions to identify and rectify potential issues. Feedback from clients is integrated throughout the process to ensure products not only meet technical specifications but also address practical application needs.

Requirement Analysis

We engage in in-depth communication with our clients to clarify key requirements for the engine components, including function, performance, quality, cost, and delivery timelines. This ensures the product is tailored to the actual application scenario from the very beginning of the design phase.

Conceptual Design

Based on client requirements, our engineering team develops preliminary designs for structure, materials, and configuration. Multiple feasible solutions are generated, and direction is confirmed with the client through conceptual sketches.

Detailed Design

Utilizing advanced CAD software, we conduct detailed and refined design work. This phase encompasses critical factors such as manufacturing processes, assembly methods, interface design, mechanical properties, and thermal performance, ensuring the design drawings are both manufacturable and deliver high performance.

Analysis & Simulation

We employ methods such as Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), and dynamic simulation to verify the component's performance and reliability under extreme operating conditions. This allows for the early identification and optimization of potential issues.

Material Selection & Prototyping

We meticulously select high-quality materials and employ advanced processes like casting, forging, stamping, welding, and machining for prototyping. This ensures that the samples fully comply with design requirements regarding dimensional accuracy, surface quality, and mechanical properties.

Testing & Validation

Comprehensive tests, including static, dynamic, endurance, and environmental adaptability tests, are conducted in our professional laboratories. We ensure the components meet or even exceed relevant industry standards.

Modification & Optimization

Based on the testing and validation results, our R&D team may implement modifications and optimizations to the components. This could involve adjusting design parameters, improving manufacturing processes, or adding protective features.

Technical Documentation

Throughout the R&D process, our team compiles all relevant technical documentation, including design drawings, process files, test reports, and user manuals.

Mass Production & Assembly

We leverage automated production lines and a strict quality control system to achieve efficient and stable mass production. Every manufacturing step undergoes multiple inspections to ensure product consistency and reliability.

After-Sales Service & Technical Support

We provide comprehensive after-sales support, including technical training, fault diagnosis, and maintenance services, ensuring our clients experience trouble-free operation and full support throughout the product lifecycle.

R&D Advantages

Advanced R&D for Reliable Automotive Components

Material Insight

We evaluate and select high-grade metals, alloys, and polymers to ensure every component performs reliably under heat, pressure, and long-term engine use. Each material choice supports stable operation across a wide range of vehicle applications.

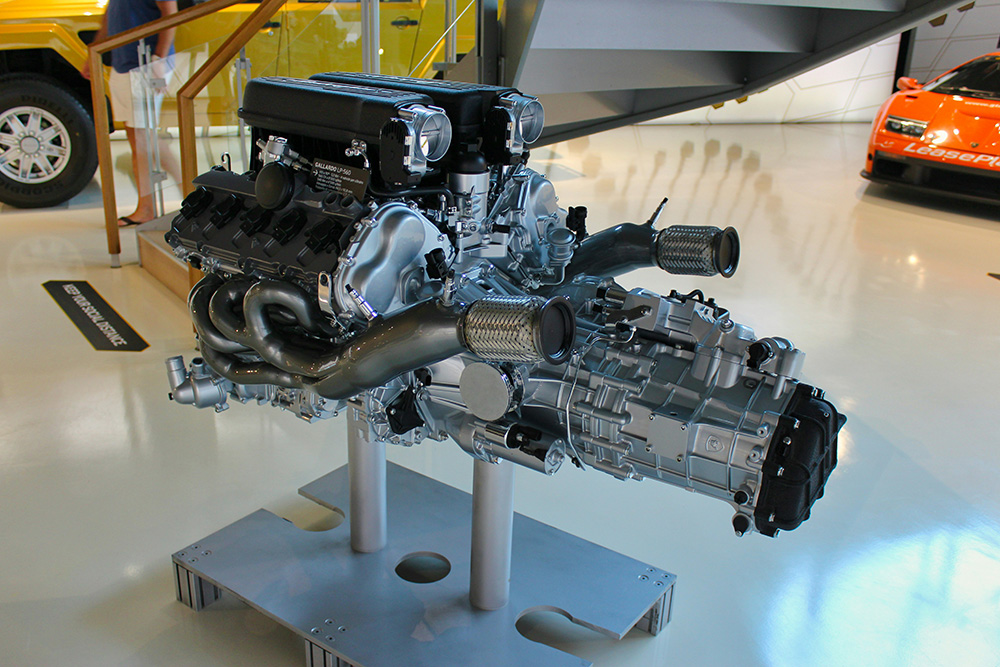

Precision Engineering

Our engineering team applies accurate modelling and strict dimensional control to create parts that match OEM fitment and performance requirements. This precision helps reduce wear, noise, and installation issues in real-world use.

Technical Innovation

Through continuous improvement and updated design methods, we introduce practical innovations that enhance efficiency, durability, and engine responsiveness. Our R&D approach focuses on bringing real value to workshops and distributors.

Performance Validation

Every component goes through structured durability checks, functional simulations, and road-condition testing. These validation steps confirm that the part delivers steady, long-term performance once fitted to the customer’s vehicle.

Design Optimisation

We refine part geometry, weight balance, lubrication flow and mechanical structure to improve function and extend service life. This optimisation ensures the components can handle modern engine demands and different driving conditions.

Application Expertise

Our development work is supported by deep understanding of major global engine platforms. By analysing OEM structures and usage patterns, we create parts that meet the needs of professional buyers across multiple automotive markets.

Testing & Validation

Ensuring Every Component Meets OEM Standards

Every prototype and production component undergoes comprehensive, multi-stage testing to guarantee it consistently meets OEM-level standards while delivering reliable, long-term performance under real-world operating conditions.

- Dimensional accuracy and tolerance verification

- Functional performance tests under real operating conditions

- Thermal cycling and high/low-temperature resistance

- Pressure and flow testing for oil pumps and cooling systems

- NVH (noise, vibration, and harshness) evaluation

Advanced Equipment

Advanced Facilities for Precision and Reliability

Every prototype and production component undergoes comprehensive, multi-stage testing to guarantee it consistently meets OEM-level standards while delivering reliable, long-term performance under real-world operating conditions.

Comprehensive Fitment

R&D Capability Covering All Major Global Engine Brands

Our R&D team has deep expertise across major global engine platforms, ensuring precise fitment and reliable performance for professional aftermarket customers through a thorough understanding of OEM designs and real-world operating requirements.

We provide dedicated engineering solutions for:

- Mercedes-Benz engine components

- BMW engine components

- Jaguar Land Rover applications

- Isuzu engine systems

- VW engine components

- Peugeot engines

- Additional mainstream and niche global models

Continuous improvement

Continuous Improvement & Future Development

We integrate feedback from workshops, distributors, and industry data to refine designs, improve durability, and increase efficiency. Future development focuses on:

- Lighter, more efficient structures

- Improved valve timing and lubrication systems

- Enhanced durability for next-generation engines

- This commitment ensures our components remain competitive and aligned with evolving market needs.

quality assurance

Commitment to OEM-Level Standards

Our commitment to quality begins at the earliest stage of development, where each design is evaluated for durability, efficiency, and long-term stability. Through controlled material selection, precise engineering, and comprehensive validation, we ensure every component meets the demands of modern engines and professional buyers. Our rigorous adherence to quality standards ensures reliable, well-engineered components for the aftermarket and distribution networks.

- Ensures dimensional accuracy, fitment, and functional consistency

- Provides professional buyers with confidence in long-term performance

- Guarantees compatibility with European and global engine platforms